Chimney Liners

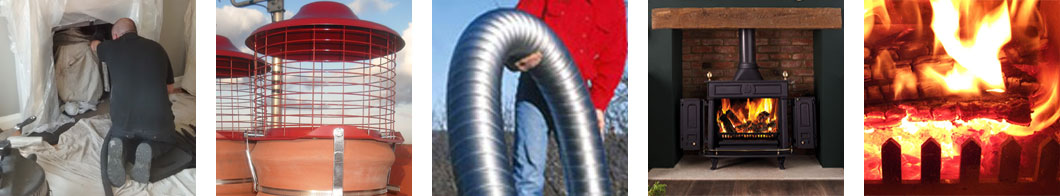

For a stove to work successfully, it must be connected to a sound chimney and correctly sized flue.

The functions of a chimney are to safely remove the products of combustion from the appliance to the outside without causing danger to the occupants or risk setting the house itself on fire.

A chimney works on a simple principle "Hot Air Rises", therefore the flue must be well insulated for this to happen.

Before proceeding further it is important to understand the terms used: -

- FLUE - The flue is the passageway through which the products of combustion travel to the outside from the stove.

- CHIMNEY - This is the structure surrounding the flue or flues.

- FLUE LINER - The material used to form the flue.

- STOVE PIPE - The pipe connected from the appliance to the flue within the chimney.

Factors, such as operating a stove at a low setting for long periods or cool air leaking into the flue, will cool the gases down and affect the performance of the chimney. To keep the flue gases warm, consideration must be given to the insulation value of the lining within the chimney.

Most houses built prior to 1965 (before a change in the Building Regulations) were built without liners. Flues were usually "parged" (rendered) on the inside with lime mortar. This parging, over a period of time, will have suffered attack from the corrosive elements within the flue gases, resulting in erosion and leakage. This can generally be noted by a sand like material falling down the chimney (the old lime mortar) also the mortar between the bricks will have deteriorated in the same way.

Houses built after 1966 should have lined flues; this is usually done with clay liners. However, this type of lining is not necessarily suitable for an efficient wood or multi-fuel stove.

Very often, chimneys are built on the outside of the house and are therefore subjected to the elements. This combined with the fact that insulation around the liners is generally excluded all adds up to a cold flue.

Please remember that stoves are efficient heating appliances and will produce anything up to 85% of heat from the fuel burnt into the room, unlike an open fire that can lose up to 95%. With little heat loss from an efficient stove, it becomes understandable how essential it becomes to retain a reasonable flue gas temperature in order to achieve a natural rise.

A lined and well insulated flue will produce an efficient and safe appliance. Unlined flues can result in costly redeemable building work.

What are the reasons for lining a chimney?

Here are a number of reasons why an old chimney may need lining. These can be summarised as follows: -

- The flue is leaking smoke and fumes into other rooms or parts of the building.

- Condensation or tar are seeping through the chimney walls causing staining either outside or inside the building.

- The flue is much too large for the type of appliance being used.

- The flue is too cold, particularly if on the outside wall and consequently not drawing properly.

- If the chimney was built from 1965 onwards with liners installed the wrong way up, tar and condensation leakage may occur. Regrettably, this is quite a common occurrence and I have seen far too many of these chimneys especially in the Brighton and Eastbourne area.

- The old flue surface is eroded, causing leakage, chilling and poor up draught.

What is the appropriate chimney liner for your appliance?

There are two types of flue liner. Class 1 (for wood and solid fuel) and Class 2 (for gas).

Class 1 Liners

All wood and multi-fuel stoves must be installed with Class 1 flue liner. There are a number of different types of Class 1 lining material available.

We list as follows:

- Rigid 316 grade stainless steel

- Pumped refractory concrete (Thermocrete)

- Rigid pumice

- Flexible 316 grade stainless steel

The Class 1 flexible 316 grade stainless steel liners are the most cost effective means of lining an existing chimney. The work can generally be carried out in one day with minimum upheaval and little mess. Installed correctly, it will last many years and also carries a long guarantee. Generally, this liner is recommended by chimney lining companies since they have used this method for over 20 years with very few failures.

All chimneys need to be swept prior to fitting a liner for a number of reasons including:

-To keep the mess to a minimum on the day of lining the chimney

-To check the flue way is clear of blockages and birds nests. It would defeat the object to install a chimney liner against a dirty chimney and run the

risk of a chimney fire.

And finally, most liner manufacturers give a ten year guarantee and having your chimney swept prior to installing the liner is one of the conditions.

Class 2 Liners

The Class 2 flexible flue liner could easily be mistaken for a Class 1 liner.

Points to watch out for:

- It is inexpensive.

- It is lightweight.

- It is not smooth on the inside.

All gas stoves should be lined with a Class 2 liner to meet safety regulations.

Closed circuit television (CCTV) surveys

Sometimes, owing to the way the chimney has been built, we may not be able to make a simple visual check to determine if anything is wrong. This is where a specialised CCTV inspection comes in really useful. Ansells can offer an chimney inspection service that makes use of a camera that is guided up the flue, taking the same route that the brush would. We can then see the void of the chimney on our monitor and the footage is recorded to DVD. This often means that on future call outs, we'll know what and where the problem area was just by reviewing the DVD footage.

A CCTV inspection can be particularly good for assessing damage, or when seeking a quote for repair work or even showing evidence to an insurance company before or after a repair. The great thing about CCTV cameras is that they can often access any dry cavity, such as a chimney, that would be difficult or impossible to access therwise.

Why not call Ansell Chimneys now for a free quote

If you would like to know more or are interested in a quote we would be happy to help. Phone us on 01923 661 614, email us at info@ansellchimneys.co.uk or fill in our enquiry form and we will be in touch as soon as possible.

Ansell Chimneys

t. 01923 661 614 | m. 07941 282 325 | m. 07976 318 160 | Email us

t. 01923 661 614

m. 07941 282 325

m. 07976 318 160

Email us

Abbots Langley

Barnet

Borehamwood

Bovingdon

Bricket Wood

Bushey

Chorleywood

Croxley Green

Elstree

Harpenden

Hemel Hempstead

Kings Langley

Little Chalfont

Northwood

Pinner

Potters Bar

Radlett

Rickmansworth

Shenley

South Oxhey

Sarratt

Stanmore

St Albans

Tring

Watford

Abbots Langley | Barnet

Borehamwood | Bovingdon

Bricket Wood | Bushey

Chorleywood | Croxley Green

Elstree | Harpenden

Hemel Hempstead | Kings Langley

Little Chalfont | Northwood

Pinner | Potters Bar

Radlett | Rickmansworth

Shenley | South Oxhey

Sarratt | Stanmore

St Albans | Tring

Watford

Abbots Langley | Barnet | Borehamwood | Bovingdon | Bricket Wood

Bushey | Chorleywood | Croxley Green | Elstree | Harpenden

Hemel Hempstead | Kings Langley | Little Chalfont | Northwood | Pinner

Potters Bar | Radlett | Rickmansworth | Shenley | South Oxhey

Sarratt | Stanmore | St Albans | Tring | Watford

Abbots Langley | Barnet | Borehamwood | Bovingdon | Bricket Wood | Bushey

Chorleywood | Croxley Green | Elstree | Harpenden | Hemel Hempstead | Kings Langley

Little Chalfont | Northwood | Pinner | Potters Bar | Radlett | Rickmansworth

Shenley | South Oxhey | Sarratt | Stanmore | St Albans | Tring

Watford